Customized Service

LONGi operates its own laboratory within our manufacturing center, which is a state-of-the-art magnetic separation engineering facility. This laboratory undertakes professional sample testing and reporting for a wide range of mineral and recycling industries.

Quality Magnets

Magnets with a high coercive force are used in our products to ensure a stable and reliable performance. The demagnetization rate is on average less than a 5% change over a 8 year span.

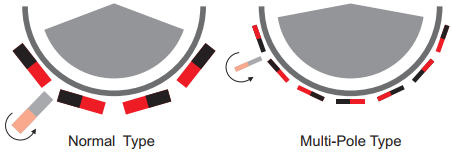

Multi-pole Magnet Structure

Our multi-pole magnetic structure helps improve the concentrate grade by encouraging the material to agitate and flip over on the drums service. This allows non magnetic particles to escape while keeping the ferrous material firmly in place.

Magnetic Separators for Wet Mineral Processing

High-Performance Magnet System

The multi-pole design with small gaps creates an environment that offers a thorough separation.

Large wrap angle, long pickup area.

High gradient magnetic field.

The total magnetic system, with the above improvements, raises both the concentrate grade and recovery rate very effectively and efficiently.

Efficient Separation Tank

LONGi has created a hydro dynamically efficient curve for the tank arc which enables it to prevent large particles from blocking it during the primary pass. In addition the tanks are built from stainless steel with special wear material in the impact area.

Adjustable Design

The tanks are created to be adjusted in all directions in able to allow you to create the best environment to get the maximum amount of recovery at the highest grade according to your unique conditions.

Spray Nozzle

By using an exclusive to LONGi design our spray nozzles are able to effectively remove concentrate from the drum while utilizing less water.

Magnetic Separators for Dry Mineral Processing

The N40H magnets used are long lasting and of a high magnetic force. Each is protected by a chromium plating. The demagnetization is less than a 5% change per every 8 years.

The assembly of the magnetic system is such that the magnets are fixed onto a yoke plate with stainless steel bolts and then wrapped with a stainless steel plate to prevent damage and peeling of the magnets.

Precautions such as sealant on the machining surface, stainless steel flanges, the drum shell being 4mm with a sealing ring and the like are used to protect the drum from dust, water and moisture to enable for a long term stable operation.

The drum surfaces are protected with wear resistant ceramic plates with the following features:

Durable and Wear Resistant

The hardness of the ceramic plate is up to HRA92, which is 100 times that of manganese steel and 20 times that of cast chromium iron.

Unable To Become Magnetized

Since the ceramic plates are unable to become magnetized they are even more resistant to wear from tramp metal.

Highly Efficient

The intrinsic properties of the ceramic plates help to improve the separation efficiency and grade of the materials processed.

Safe and Reliable

The ceramic plates are affixed with a high intensity non-magnetic polymer. The shear strength between the shells and plates are more than 30MPa. Due to this extreme strength they are well suited for the extreme changes of temperature and vibrations found in operation.