FLEXCO® XP™Staple Belt Fastening System

- Feb 2, 2024

- 2 min read

Premium Quality Staple System

Extreme Performance Where It’s Most Important:

• A tool that can skip over misdrives without starting over

• One handle controls both advance and fastener installation

• Durable loop area provides up to 33% longer splice life

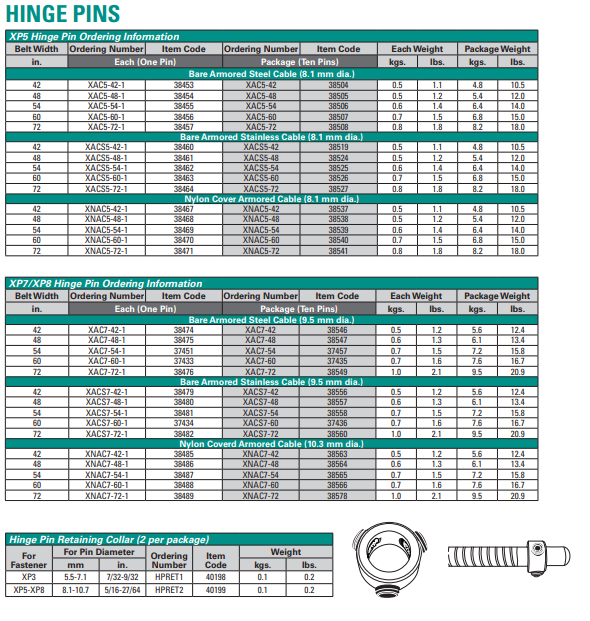

XP™ Fasteners and Hinge Pin

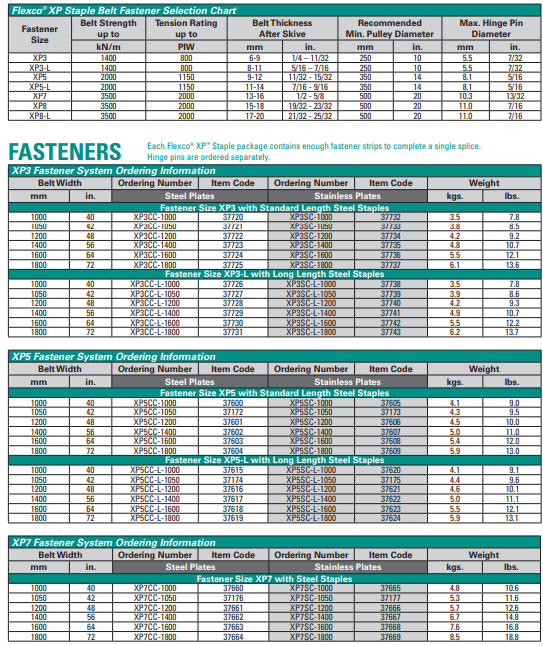

No matter what the belt condition, Flexco® XP™ fasteners are a good choice for both new and older, worn belts. XP staple fasteners can be used on belt thicknesses ranging from 6 to 20 mm (1/4”– 25/32”) after skive with pulley diameters over 250 mm (10”). The fasteners are designed to be used with belt strengths up to 3500 kN/m and operating tensions of 2000 PIW. Available with steel and stainless fastener plates.

Why Staple Fasteners?

• Belt Strengths up to 3500 kN/m. Tension Rating up to 2000 PIW.

• Works well in harder belting such as solid woven PVC/PVG types

• Staples are preset in fastener

• Staple lengths handle a wide range of belt thicknesses.

• Can adjust compression on worn belt

• Applicator Tools: manual and powered

The XP™ Applicator Tools are easy to set up, operate, and transport. Unlike similar designs, the XP™ sets one fastener at a time so misdrives and tool jams are infrequent. And, should an occasional misdrive occur, the design allows the operator to skip over it and continue with the splice.

The XP™ Power Applicator Tools have a sealed housing that is easy to maintain. They mount quickly to the frame and are easily positioned for splicing. One smooth motion of the lever compresses the plate, then drives and folds the staples for the same consistent staple set and finished splice profile each and every time.

Combine fasteners, hinge pin, applicator, and tool frame to complete the system. Use the selection charts below to choose the combination that is right for your operation