Flexco Secondary Cleaners

- Bolkar Altuntas

- Feb 1, 2024

- 9 min read

Updated: Apr 29, 2024

MHS ® RETROFITS for Richwood® 1C-ITC Secondary Cleaners

Designed to seamlessly integrate into existing 1C-ITC secondary cleaner framework.

Features and Benefits

• Cleaning efficiency of metal blades. The thin, hard edges of the metal blades deliver high cleaning efficiency and long wear life.

• Works with Flexco mechanical splices. The C-Tip tungsten carbide blades are impact-resistant and are for use on belts with mechanical fasteners. V-Tips can be used only on vulcanized belts.

• Made from heavy-duty, corrosion-resistant steel. The MHS and U-Types are available in sizes for belt widths from 18” to 84” (450 to 2100mm). Additional sizes are available upon request.

MHS Heavy-Duty Secondary Belt Cleaner

The MHS Heavy-Duty Stainless Steel Secondary Belt Cleaner was designed to deliver and maintain superior cleaning efficiency, even on the most demanding, abusive beltlines. The MHS SS is the new answer to tough belt cleaning problems. It delivers high-efficiency cleaning and long-lasting performance, with low maintenance.

Features and Benefits

• Stainless steel. Corrosive environments wear on any component, but stainless steel can protect against that.

• Cleaning efficiency of metal blades. The thin, hard edges of the metal blades deliver high cleaning efficiency and long wear life.

• Works with Flexco and other mechanical splices. The C-Tip tungsten carbide blades are impact resistant, and the spring cushion allows them to move away from a passing splice without damage and with minimal cleaning disruption. The V-Tip can be used on vulcanized belts.

• Made for mining conveyors. Made from heavy-duty, corrosion-resistant stainless steel, the MHS is available for belt widths from 24" to 96" (600 to 2400mm). Additional sizes are available upon request.

• Complete cleaning system. When the MHS is teamed with the MMP Precleaner, the system provides maximum cleaning power for tough applications.

• Safe to service. All service can be performed from a safe position at the side of the conveyor.

MHS Enhanced Service Advantage Cartridge HD Secondary Belt Cleaner

The MHS Enhanced Service Advantage Cartridge Secondary Belt Cleaner joins our proven and patented PowerFlex cushion with a superior, service-friendly removal cartridge. The MHS ESAC Cleaner delivers the high-efficiency cleaning and long-lasting performance required for the most difficult cleaning environments. The cartridge now gives you control over maintenance with three easy-to-use removal options, ensuring greater ease of maintenance.

EZS2 Rockline® Secondary Cleaner

The EZS2 Secondary Belt Cleaner improves belt cleaning efficiency and reduces routine maintenance tasks. And it does all of this at an affordable price. Add easy, do-it-yourself installation and it makes an unbeatable solution for your conveyor belt cleaning needs.

Features and Benefits

• Cleaning efficiency of metal blades. The thin, hard edges of the metal blades deliver high cleaning efficiency and long wear life.

• Works with Flexco mechanical splices. The tungsten carbide-tipped blades are impact-resistant, and the spring cushion allows them to move away from a passing splice without damage and with minimal cleaning disruption.

• A complete cleaning system. When the EZS2 is teamed with the EZP1 Precleaner, the system provides maximum cleaning power for tough applications.

• Fits most conveyor structures. Available for belt widths from 18" to 72" (450 mm to 1800 mm).

FMS Secondary Cleaner

The FMS Secondary Belt Cleaner features carbide blades, self-adjusting spring tensioners and unique cushions that independently tension each blade to the belt. This simple but durable design provides quality cleaning performance at an affordable price.

Features and Benefits

• Made for mining conveyors. Made from heavy-duty steel with corrosion-resistant powder coating, the FMS is available in sizes for belt widths from 18" to 72" (450 to 1800mm). Additional sizes are available upon request.

• For belt speeds up to 1000 fpm (5M/s).

• Compact spring tensioner. Utilizes the MST tensioner to maintain constant pressure on the belt.

• Cleaning efficiency of metal blades. The thin, hard edges of the 6" (150mm) wide metal blades deliver high cleaning efficiency and long wear life.

• Works with Flexco mechanical splices. The C-Tip tungsten carbide blades are impact-resistant, and the spring cushion allows them to move away from a passing splice without damage and with minimal cleaning disruption. V-Tips can be used only on vulcanized belts.

• A complete cleaning system. When the FMS is teamed with the MSP or MMP Precleaner the system provides excellent cleaning power for tough applications.

MDWS Heavy-Duty Secondary Belt Cleaner

Many times the belt cleaners on a beltline do a good job of taking off the carryback materials. However, after the last cleaner, there is still water on the belt and that can still cause a big mess along the beltline. The MDWS Secondary Belt Cleaner is designed to be the last cleaner in a cleaning system and wipe the belt dry.

Features and Benefits

• Long wear life. Blade has 4-1/2" (113 mm) of usable urethane.

• Low maintenance. Occasionally check for blade wear and measure springs for proper tensioning.

• Works with mechanical fasteners. The polyurethane blade easily glides over the mechanical splices and the spring tensioners dampen any impact, allowing the splices to pass without damage to the blade or the splice and with minimal cleaning disruption.

• Streamlined design. The MDWS has minimal horizontal surfaces for carryback to build up on. Carryback buildup often renders other secondary cleaners ineffective.

• Complete cleaning system. When teamed with a Mineline precleaner and one or more secondary cleaners depending upon the application, the MDWS is the unbeatable final cleaner in a cleaning system that delivers unmatched cleaning performance and efficiency. • Made for mining conveyors. The MDWS comes standard with an extra-long pole (belt width plus 60" (1500 mm) for cleaners up to 60" (1500 mm) and belth width plus 54" (1350 mm) for cleaners over 60" (1500 mm)), so it can be used on most mining conveyors. It is available for belt widths from 24 to 96" (600 to 2400 mm).

CHEVRON Belt Cleaner

Chevron, cleated and raised rib belts present a special problem for efficient cleaning. However, not cleaning these belts lets the carryback move along the return belt and cause all the familiar problems: mistracking, buildup and premature wear on idler rollers and resulting belt wear and damage. Flexco’s Chevron Belt Cleaner takes a new approach to cleaning these problem belts.

Features and Benefits

• Free-rotating. Works only when the belt runs.

• Self-cleaning. Finger length, spacing, and the rotary action allows the carryback to fall free instead of clogging.

• Long-wearing SBR rubber. Drum life ranges from 1 to 3 years depending upon the application conditions and the material being conveyed.

• Easy to install. Few parts and easy-to-use installation instructions make the job simple.

• Works on mechanically spliced or vulcanized belts.

• Works on reversing belts.

MOTORIZED BRUSH CLEANER

Chevron, cleated and raised-rib belts present a special problem for efficient cleaning. The Motorized Brush Cleaner is an ideal option for cleaning these belts. It also performs well as the second or third cleaner in a system with worn or pitted belts, as the bristles effectively dislodge trapped material.

Features and Benefits

• Maximum Cleaning. Spins opposite the belt direction for optimal cleaning.

• Uniquely patterned bristles. Aids in reducing material buildup and clogging.

• Adjustable tensioners. Allows easy brush-to-belt adjustment as the bristles wear.

• Works on mechanically spliced or vulcanized belts.

P-TYPE® Secondary Belt Cleaner

The Flexco P-Type® Secondary Belt Cleaner is compact and designed to be positioned just off the head pulley to remove carryback from the belt. Stand alone, or when used in conjunction with a precleaner, the P-Type cleaner is a reliable choice for maintaining a highly efficient cleaning system.

P-TYPE® Enhanced Service Advantage Cartridge HD Secondary Belt Cleaner

The P-Type® ESAC combines the compact and highly efficient P-Type Secondary Cleaner with the Enhanced Service Advantage Cartridge. Not only simple to install using the versatile tensioner kit, the P-Type ESAC is also trouble-free to service, with the easy-to-use cartridge kit. The cartridge now gives you control over maintenance with three easy-to-use removal options. The P-Type ESAC is the reliable choice for a great cleaner at the right price.

P-type ® LS Limited Space Secondary Belt Cleaner

The Flexco P-Type® LS Secondary Belt Cleaner is compact and designed to be positioned just off the head pulley to remove carryback from the belt. Stand alone, or when used in conjunction with a precleaner, the P-Type LS cleaner is a reliable choice for maintaining a highly efficient cleaning system.

Features and Benefits

• Cleaning efficiency of metal blades. The thin, hard edges of the metal blades deliver high cleaning efficiency and long wear life.

• Works with Flexco mechanical splices. The C-Tip tungsten carbide blades are impact-resistant, and the spring cushion allows them to move away from a passing splice without damage and with minimal cleaning disruption.

• A complete cleaning system. When the P-Type LS is teamed with a primary cleaner the system provides maximum cleaning power for tough applications.

• Fits most conveyor structures. Available for belt widths from 18" to 54" (450 mm to 1350 mm).

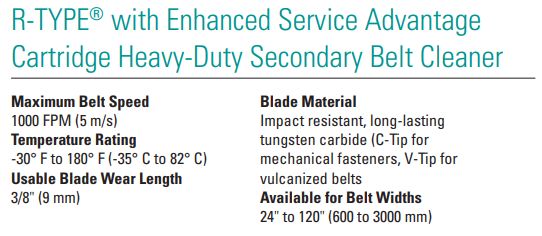

R-TYPE® Enhanced Service Advantage Cartridge HD Secondary Belt Cleaner

The R-Type® ESAC combines the reversing R-Type secondary cleaner with the Enhanced Service Advantage Cartridge. Not only simple to install using the versatile tensioner kit, the R-Type ESAC is also trouble-free to service, with the easy-to-use cartridge kit. The cartridge now gives you control over maintenance with three easy-to-use removal options. The R-Type ESAC is the reliable choice for a great cleaner on reversing belts.

U-TYPE® Secondary Cleaner

The U-Type® Secondary Belt Cleaner is designed for constant blade-to-belt contact for the highest cleaning efficiency – especially in tough applications requiring removal of water and sticky carryback materials. The U-shaped design conforms to the belt, allowing the tungsten carbide tips to shear stubborn carryback materials from the belt. No straight-blade cleaner has both the cleaning and shearing action necessary to provide the cleaning power needed in wet and sticky material applications.

Features and Benefits

• Works with mechanical splices. The impact-resistant C-Blade allows Flexco® Solid Plate fasteners and rip repairs to easily glide over the blade without recessing the splice. An F-Blade (urethane) is available for use on all types of Flexco splices. All blade types can be used on vulcanized splices.

• Blade replacement made easy with removable plate. Simply release the blade tension, loosen the bolts on the back of the cleaner pole, slide the worn blade out, insert the new blade and retighten the bolts. The job can be done in minutes.

• The final cleaner in a cleaning system. The U-Type is unbeatable as the final cleaner in a complete cleaning system. Teamed with a precleaner and in some cases another secondary cleaner, the results are unmatched in cleaning efficiency. Flexco can design a system to meet your specific requirements.

• Locking Collar on tensioner allows for easy blade-to-belt setup.

U-TYPE® Stainless Secondary Cleaner

The U-Type® Secondary Belt Cleaner is designed for constant blade-to-belt contact for the highest cleaning efficiency – especially in tough applications requiring removal of water and sticky carryback materials. The U-shaped design conforms to the belt, allowing the tungsten carbide tips to shear stubborn carryback materials from the belt. No straight-blade cleaner has both the cleaning and shearing action necessary to provide the cleaning power needed in wet and sticky material applications.

Y-TYPE™ Polyurethane and Carbide Secondary Cleaner

The Y-Type™ Secondary Belt Cleaner improves belt cleaning efficiency and reduces routine maintenance tasks. With an easy, do-it-yourself installation and simple, serviceable blades, all at an affordable price, it makes for an ideal solution for your belt cleaning needs.

Features and Benefits

• Belt speeds up to 600 fpm (3M/s) for standard duty, up to 750 fpm (3.8M/s) for heavy duty.

• Works on reversing belts.

• Available in 18" - 48" (450 - 1200mm) for standard duty belts, 36" - 72" (900 - 1800mm) for heavy duty belts.

• 3" (75mm) wide blade segments. Conforms to worn or damaged belts.

• Blades available in carbide and purple or white/food grade polyurethane.

• Easy maintenance. Simple design makes changing the blades fast and easy. Blades can be removed and replaced individually, or all at once by replacing the cartridge.

• Spring tensioner. Utilizes the YST tensioner to maintain constant pressure on the belt. Standard duty YST for 2-3/8" (60mm) poles, heavy duty YST for 2-7/8" (73mm) poles.

• White food-grade blade is chemical resistant, and all ingredients used in polyurethane formulation comply with the relevant requirements of 21 CFR (FDA Code of Federal Regulations) for use in repeated bulk dry food applications.

V-PLOW Belt Plows

Keeping your conveyor beltlines clean is a problem that is not confined to the head pulley area. Many times rocks, lumps of carryback and other debris get into the tail pulley and cause damage to the belt, lagging and mechanical splices. This can lead to belt tracking problems and other maintenance and repair expenses. The V-Plow is uniquely designed to clean the inside of the return belt and eliminate nagging problems.

Features and Benefits

• Reduces belt mistracking. Material build-up on a pulley causes belt mistracking problems which can lead to other problems on the conveyor. The V-Plow removes those materials before they get into the pulley and begin building up. • Discharges to both sides of the belt. The plow is angled to discharge materials to both sides of the belt, making it as convenient as possible for cleanup.

• Can be used anywhere on the beltline. The V-Plow can be installed on the inside of the return belt anywhere there is a problem with materials falling onto the belt. Many times it is installed just behind the head pulley to dump carry-back before it travels down the beltline.